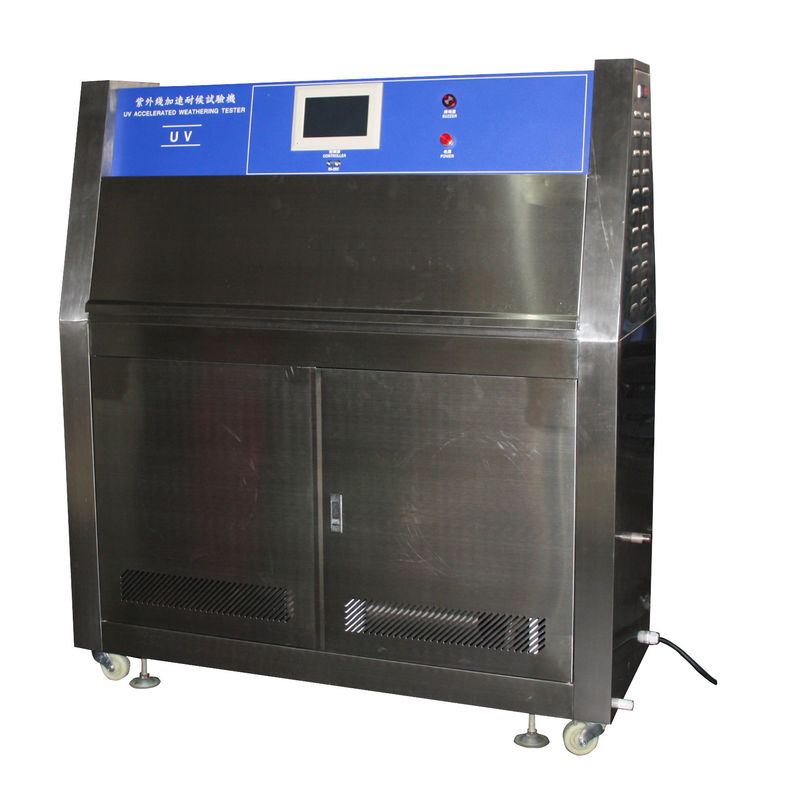

ASTM D4329 UV Accelerated Aging Test Chamber For Leather Plastic

Product Details:

| Place of Origin: | Guangdong, China |

| Brand Name: | GAOXIN |

| Certification: | ISO 2009 |

| Model Number: | GX-3050 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard Exporting Wooden Case |

| Delivery Time: | 15 work days |

| Payment Terms: | FOB Shenzhen T/T |

| Supply Ability: | 50 per months |

|

Detail Information |

|||

| Working Room Space: | 450×1170×50mm | Outside Volume: | 580×1280×145mm |

|---|---|---|---|

| Temperature Range: | RT+10℃~70℃ | Humidity Range: | 90~98%R·H |

| Humidity Uniformity: | ±2% | Temperature Uniformity: | ±2℃ |

| Temperature Fluctuation: | ±0.5℃ | Humidity Fluctuation: | ±2% |

| Standard Sample: | 75×150 Mm Or 75×300mm(or Specified By User) | Water Depth: | 25 Mm, Auto Control |

| Valid UV Area: | 900×210 Mm | Ultraviolet Wavelength: | UV-A 315-400nm;UV-B 280-315nm |

| Highlight: | ASTM D4329 Accelerated Aging Test Chamber,Leather UV Accelerated Aging Test Chamber,ASTM D4329 Aging Test Machine |

||

Product Description

Ultra Violet Accelerating Aging Tester Leather Plastic UV Aging Test Chamber

Description:

The UV aging test chamber can simulate the influence of the environment including sunshine, rain and dew by exposing the sample to the controlled inter-circulation of the sunshine and moisture with the high temperature. The tester simulates the sunshine using the UV lamp, the moisture using the condensation or spray. And it is essential to the aerospace, automotive, home appliances, scientific research and other fields.

Test standard:

GB/T14522-93; GB/T16585-1996; GB/T16422.3-1997; ASTM D4329,D499,D4587,D5208,G154,G53;ISO 4892-3,ISO 11507;EN 534; EN 1062-4, BS 2782;JIS D0205;SAE J2020

Structure and Features:

(1) Material:SUS stainless steel with paint

(2) Cover material:SUS stainless steel board with paint

(3) Eight UV-A or UV-B tubes in the working room

(4) Heating method: water tank type heating with rapid speed and uniformity

(5) Box cover: Double-direction flip

(6) Automatic water supplement to avoid air burning

(7) Sample shelf: stainless steel or Aluminium alloy

(8) Mobile wheel : High quality PU wheel on the bottom of the box

(9) Drainage system: vortex type and U type deposition device

(10) The surface of the sample is parallel to that of the UV light

(11) Auto sprayer with the adjustable water pressure

(12) The machine would cut off the power supply once the door opens when it is testing to protect worker from any hurt.

(13) Over-temperature protection: The machine would cut off the power when the temperature inside is too high.

Control and System:

(1) Temperature and humidity controller: Korea high-precision digital micro-computer type integrated controller with the accuracy of 0.1℃ and resolution of ±0.1℃;

(2) Sensor: PT100 Platinum resistance temperature measurement;

(3) Control method:The thermal equilibrium temperature humidity method;

(4) P . I . D+S.S.R system control;

(5) Protection device: No-fuse protection switch; over-temperature protection; low-water level protection; over-load and electric leakage protection.

Technical Parameter:

|

Working room space |

450×1170×50mm |

|

Outside volume |

580×1280×145mm |

|

Temperature range |

RT+10℃~70℃ |

|

Humidity range |

90~98%R·H |

|

Humidity uniformity |

±2% |

|

Temperature uniformity |

±2℃ |

|

Temperature fluctuation |

±0.5℃ |

|

Humidity fluctuation |

±2% |

|

Standard sample |

75×150 mm or 75×300mm(or specified by user) |

|

Water depth |

25 mm,auto control |

|

Valid UV area |

900×210 mm |

|

Ultraviolet wavelength |

UV-A 315-400nm;UV-B 280-315nm |

|

Test time |

0~999H adjustable |

|

Blackboard temperature |

40℃~65℃ |

|

Ultraviolet light, dew time |

Alternative |

|

The machine can accept customization |

|

![]()