IEC62133 UN38.3 Environmental Simulate Test Chambers, Constant Temperature and Humidity Chamber

Product Details:

| Place of Origin: | China |

| Brand Name: | Gaoxin |

| Certification: | ISO 9001: 2008, UL |

| Model Number: | GX-3000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Non-fumigation wooden box |

| Delivery Time: | 15-25 working days |

| Payment Terms: | FOB Shenzhen, L/C, T/T, Western Union |

| Supply Ability: | 50 sets per month |

|

Detail Information |

|||

| Temperature Range: | -70℃~150°C | Humidity Range: | 5%~98 RH |

|---|---|---|---|

| Inner Chamber Volume: | 80L, 150L, 225L, 408L, 800L, 1000L | Chamber Material: | Inner: SUS304 Stainless Steel, Outer: SUS201 Stainless Steel With Paint |

| Test Chamber: | Explosion-proof | Observation Window: | Three-layer Vacuum Glass, Anti-sweat, Explosion-proof |

| Test Chamber Lighting: | High Brightness Lighting | Temperature/Humidity Adjust: | BTHC (Balance Temperature Humidity Control) |

| Highlight: | environmental testing chamber,environment test chambers,UN38.3 Environmental Simulate Test Chambers |

||

Product Description

IEC62133 UN38.3 Environmental Simulate Test Chambers, Constant Temperature and Humidity Chamber

2. Description

The programmable temperature and humidity tester also can ba named as environmental tester.

The tester Simulate the environment of low temperature, high temperature, high

temperature and high humidity, low temperature and low humidity.

It is used for testing high and low temperature, moisture resistance of various products.

3. Features

a. The tester is widely used in various industry.

b. Programmable controlling system

c. TEMI880 colorful touch screen.

4. Specifications

|

Model |

GX-3000 |

|||||||

|

Capacity |

80L |

150L |

225L |

4085L |

800L |

1000L |

||

|

Temperature range |

-70/-40/-20/0/+20 °C~+100/+150°C |

|||||||

|

Humidity range |

20/30%...98%RH |

|||||||

|

Controlling accuracy |

Temperature |

±0.3℃ |

||||||

|

|

Humidity |

±2% RH |

||||||

|

Uniformity |

Temperature |

±1.5 ℃ |

||||||

|

|

Humidity |

±3% RH |

||||||

|

Temperature raising speed |

Average 3℃/ min |

|||||||

|

Cooling speed |

Average 1℃/ min |

|||||||

|

Dimension of inner box |

W |

400 |

500 |

500 |

600 |

1000 |

1000 |

|

|

D |

500 |

600 |

750 |

850 |

1000 |

1000 |

||

|

H |

400 |

500 |

600 |

800 |

800 |

1000 |

||

|

Dimension of external |

W |

920 |

1050 |

1050 |

1150 |

1600 |

1600 |

|

|

D |

1400 |

1500 |

1650 |

1750 |

1900 |

1900 |

||

|

H |

900 |

1100 |

1200 |

1400 |

1600 |

1600 |

||

|

Test chamber materials |

Inner box: A- grade stainless steel sheet |

|||||||

|

Insulation material |

PU foam + PE foam |

|||||||

|

Refrigeration system |

Imported closed compressor / eco-friendly refrigerant |

|||||||

|

Protection device |

Fuse switch, over-pressure for compressor, over-heat, over- current, |

|||||||

|

Power |

AC 1ψ3W 220V or 3ψ5W 380V |

|||||||

|

Standard configuration |

Observation window, testing hole, shelf, time accumulator, lamp |

|||||||

|

Standards |

IEC 68-2-6(FC), GB2423, JJG189-97, GB/T13309-91 | |||||||

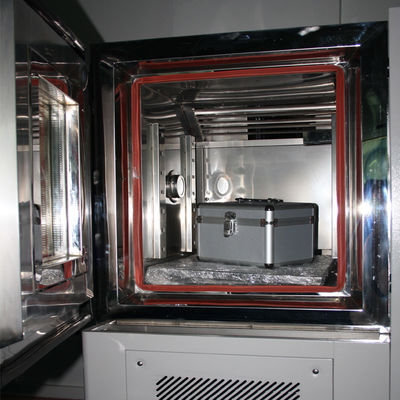

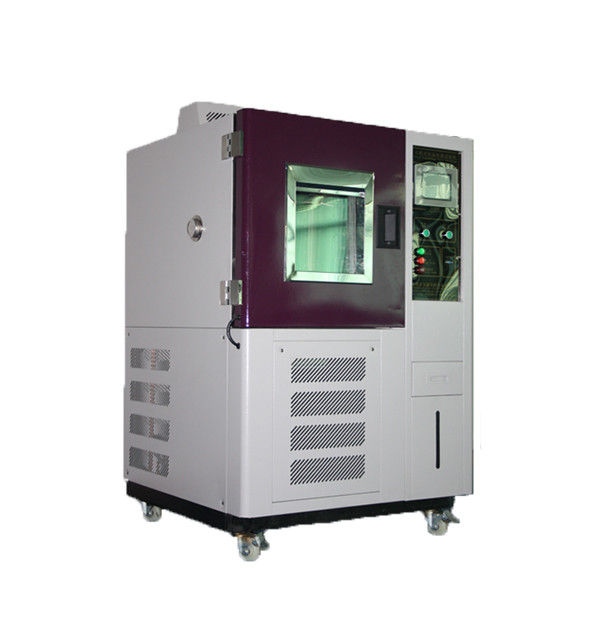

5. Pictures

![]()

![]()

![]()

![]()