150L Programmable Fast Thermal Test Chamber For Battery Testing Equipment

Product Details:

| Place of Origin: | China |

| Brand Name: | GAOXIN |

| Certification: | ISO |

| Model Number: | GX-3000-150LT |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | non-fumigation wooden box |

| Delivery Time: | 25 working days |

| Payment Terms: | T/T |

| Supply Ability: | 30 sets per month |

|

Detail Information |

|||

| Temperature Range: | -70 °C To 150°C | Humidity Range: | 20 To 98%RH |

|---|---|---|---|

| Ambient Temp.: | +5°C ~+35°C | Standard Basis: | UL 1642, UL2054, UN38.3, IEC62133, IEC 62281, IEC 60086 |

| Inner Test Chamber Dimension: | 80L, 150L, 225L 408L 800L 1000L | Temp. Constancy: | ±0.5ºC |

| Humidity Constancy: | ±2.5%R.H | Temp. Uniformity: | ±2.0ºC |

| Highlight: | Testing Machine Instruments,Industrial Test Equipment,Programmable Fast Thermal Test Chamber |

||

Product Description

Product name: Programmable High Low Temperature Test Chamber (Rapid Temperature Change Test Chamber/Thermal Cycle)

Model number: GX-3000-150LT

Equipment description

This machine is used to simulate the ability of the battery to adapt to the environment in a rapidly changing temperature environment.

Structure feature

Test Chamber dimension: 500X600X500mm

Inner box material: Mirror stainless steel plate (SUS #304 1.0mm thick);

Outer box material: A3 cold plate (1.5mm thick) vertical paint treatment;

Insulation layer structure design: effectively avoid condensation on the top of the box;

Thermal insulation layer: Insulation layer (hard Polyurethane foam + glass wool, 100MM thick);

Box Door: Box Door: has the single door on the left and the observation window. The double insulation to prevent heat exchange of inside and outside the box

Observation window: Three layers of vacuum glass for easy observation of the sample.

Observation window Size: 270x360x40MM; 3 layers vacuum sealed glass

Window anti-sweat design: electric heating device to prevent moisture condensation;

Lighting design: High-brightness window lighting for easy observation of samples;

Test hole: ψ50mm on the left side of the test chamber(for wire feed through), 1 stainless steel hole cover, 1 silicone plug;

Machine pulley: easy to move (adjust position) with powerful bolts (fixed position);

Box built-in rack: stainless steel SUS #304 square punching steel plate rack 2 pieces and track 2 sets (adjustment spacing);

Communication interface: One RS-232C terminal (9PIN). Can be connected to a computer, print curves, etc.

Product features:

1. The inner and outer boxes are connected with reliable grounding.

2. The inner box of the equipment is made of stainless steel, which is not easy to produce metal collision spark.

3.The observation window adopts explosion-proof vacuum glass to prevent the glass from breaking and injuring the operator.

4.Overtemperature protection device:The equipment is equipped with an independent overtemperature protector, namely a secondary temperature protection instrument, to prevent the risk of overtemperature in the working room.

5.Heating system:Explosion-proof heater is used.

Control system

With a wide temperature and humidity control range to meet the needs of users.

The unique balance temperature adjustment and humidity adjustment method can be used to adjust the ideal temperature and humidity environment. With stable, balanced heating and humidifying capabilities, high-precision, high-stability temperature and humidity control is possible.

Temperature and humidity control adopts touch intelligent programmable temperature regulator

(PID+SSR/SCR forward and reverse bidirectional synchronous output), including computer advanced slope control logic, with R'S-232C and 485 communication interface device, which is convenient for users long distance control And centralized control. Computer connection control, editing, recording and two sets of dynamic contacts (TIMER SINGAL RELAY), and can be equipped with temperature recorder.

All components of heating, cooling, humidifying and dehumidifying are completely controlled by microcomputer. The system is completely independent. It is equipped with intelligent controller, which greatly improves the setting precision.

Program correction, clearing, scheduled start, power failure memory, etc.

Automatic selection of the refrigeration circuit: The automatic control device has the function of automatically selecting the running refrigeration circuit with the set value of the temperature, and start the refrigerator to cool down under the high temperature state. The refrigeration adopts the air-cooled compressor group and adopts the fully enclosed compressor

The door is equipped with a light observation window for easy observation of the test condition of the test sample.

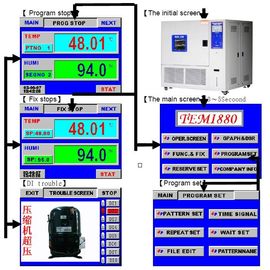

Touch screen smart programmable temperature regulator

Microcomputer large LCD (320*240 dots) Chinese and English display control system, LCD touch panel, backlight 17 adjustable, curve display set value display value, curve and display a variety of alarms, Display faults through the screen, eliminate misoperations, multiple sets of PID control function, and in a form of data displayed on the screen

Temperature and humidity electric heating circulation system

Heating system: fin heat pipe type stainless steel electric heater;

Circulatory system: special moisture-proof and heat-dissipating design, stainless steel extended shaft circulating motor, with high-temperature, low-temperature aluminum alloy multi-blade fan blades;

Air deflector design: can be adjusted up, down, left and right to ensure uniform distribution of temperature and humidity;

Control method: Balanced temperature control system (BTHC), the SSR is controlled by P.I.D., so that the heating and humidifying amount of the system is equal to the amount of humid heat loss, so it can be used stably for a long time.

Freezing system

Refrigeration system: European and American high-efficiency power-saving ultra-low temperature refrigeration system (air-cooled heat dissipation method);

High-efficiency compressor: 2 P (2 sets) of fully enclosed compressors from TECUMSEH

Refrigeration method: Two-stage compressor refrigeration system

Cold and heat exchange system: Ultra-high efficiency SWEP refrigerant cold heat exchange design (environmental refrigerant R404A);

Heating load adjustment: Automatically adjust the refrigerant flow, effectively taking away the heat generated by the heat load;

Condenser: Fin type with cooling motor;

Evaporator: Fin type multi-stage automatic load capacity adjustment;

Expansion System: Capacity Controlled Refrigeration System, Danfoss Brand

Other accessories: desiccant, refrigerant flow window, repair valve;

Security system

Over temperature protector

Zero-crossing gate fluid power controller

Air-burning protection protector

Under phase reverse phase protection switch

Compressor high voltage protection switch

Compressor overheat protection switch

Compressor overcurrent protection switch

No fuse switch

Ceramic fast fuse

Line fuse and fully sheathed terminal

Buzzer

Equipment conditions of use

Laboratory temperature range 0~35°C

Relative humidity: no more than 85%

Large air pressure: 86~106Kpa

No strong vibration around

Direct sunlight or direct exposure to other heat sources

Natural drainage facility

Power supply conditions: Three-phase four-wire power supply, reliable grounding

Standard List

![]()

-

Main machine 1 Set

-

Sample shelf2 PCS

-

Silicone plug2 PCS

-

Product certification 1 Copy

-

Manual 1 Copy