Battery Impact testing Equipment Gravity Impact Tester UN 38.3.4.6 & IEC 62133

Product Details:

| Place of Origin: | China |

| Brand Name: | Gaoxin |

| Certification: | ISO 2008 |

| Model Number: | GX-5066-NE |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiation |

| Packaging Details: | Non-fumigation wooden box |

| Delivery Time: | 25 working days |

| Payment Terms: | FOB Shenzhen, L/C, T/T, Western Union |

| Supply Ability: | 50 sets per month |

|

Detail Information |

|||

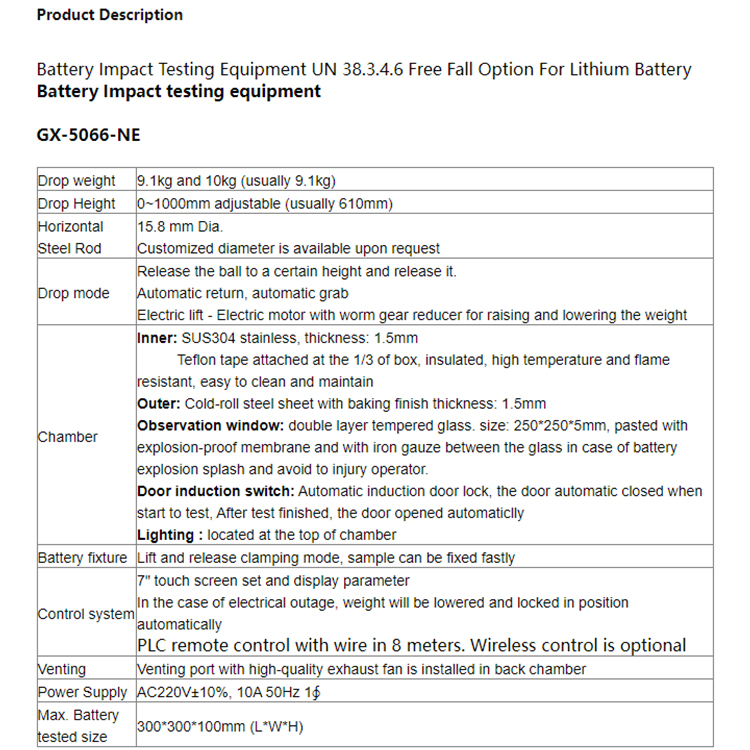

| Falling Ball Weight: | 9.1kg | Control System: | PLC Touch Screen Control And Display |

|---|---|---|---|

| Impact Mode: | Automatic Return, Automatic Grab | Horizontal Bar: | Diameter Of 15.8 Mm (5/8 Inch) |

| Impact Height: | 610 Mm ± 25 Mm (0~1000mm Adjustable) | Max. Battery Tested Size: | 300*300*100mm (L*W*H) |

| Testing Item: | UN38.3 T6 Impact | ||

| Highlight: | Testing Machine Instruments,Industrial Test Equipment |

||

Product Description

1.How can we guarantee quality?

Our Products have passed the certification of China National Standard System. The products have been tested according toGB/UN/UL/IEC/SAE/ISO/TAPPI/AATCC/ASTM/EN/DIN/JIS. The company has a complete organizatinal structure and management system,through the ISO9001 quality management system, ISO14001 environmental management system certification.

2.What can you buy from us?

Our products include battery testing equipment, leather testing equipment, footwear testing equipment, tensile testing machine,

environmental test chamber, paper testing machine etc.

3.What details are required for a quotation?

What is the test standard

What product or material testing from this machine

What is the Test object size

What is you want the machine appropriate size

4.Can I make changes before I ship?

No,it can not change if machine finished

5.When will my order ship?

Need 10-45 workdays base on which type the the machine

6.How can I track my order?

We will send the schedule by each stage

Our Products have passed the certification of China National Standard System. The products have been tested according toGB/UN/UL/IEC/SAE/ISO/TAPPI/AATCC/ASTM/EN/DIN/JIS. The company has a complete organizatinal structure and management system,through the ISO9001 quality management system, ISO14001 environmental management system certification.

2.What can you buy from us?

Our products include battery testing equipment, leather testing equipment, footwear testing equipment, tensile testing machine,

environmental test chamber, paper testing machine etc.

3.What details are required for a quotation?

What is the test standard

What product or material testing from this machine

What is the Test object size

What is you want the machine appropriate size

4.Can I make changes before I ship?

No,it can not change if machine finished

5.When will my order ship?

Need 10-45 workdays base on which type the the machine

6.How can I track my order?

We will send the schedule by each stage

Want to Know more details about this product